Product Category

OUR HEAT EXCHANGERS

OUR HEAT EXCHANGERS

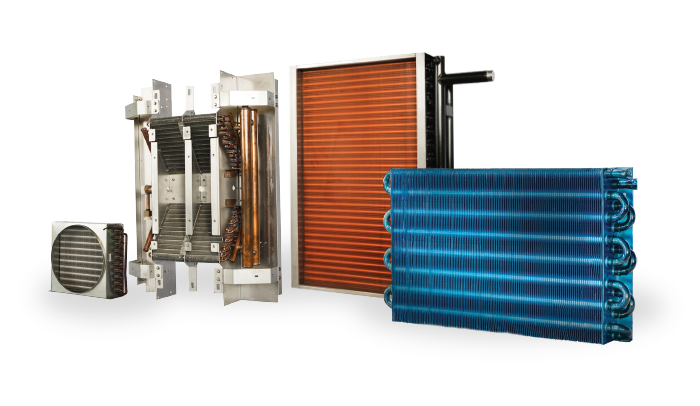

CIG makes virtually every type of round tube / plate fin (RTPF) coil and heat exchanger, including water coils, condenser coils, and evaporator coils, for both air conditioning and refrigeration, whether for residential OEM air conditioners or one-off made-to-fit and custom commercial coils. We make transport refrigeration coils, truck and bus air conditioning coils, marine coils, and industrial coils. We make coils. Any kind, any size, we can do it.

Quality Products

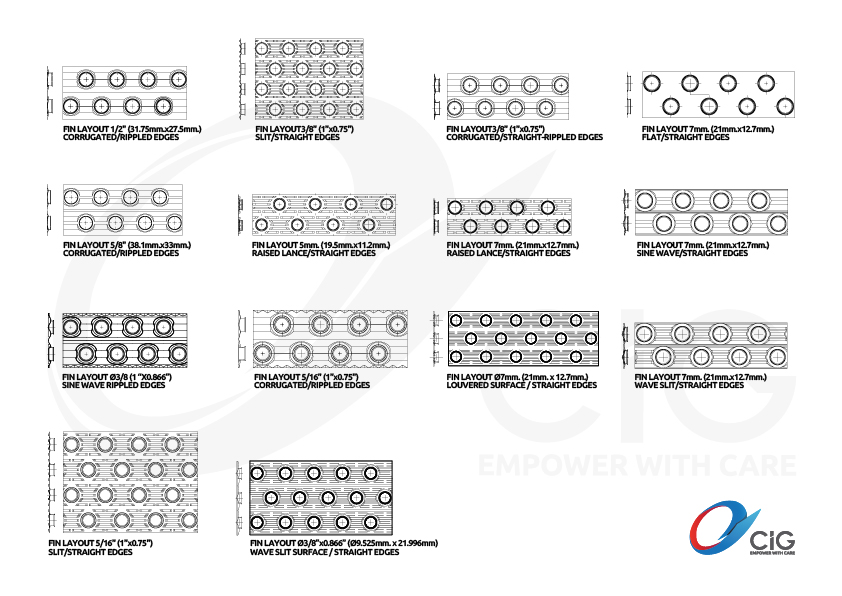

We use seamless copper and aluminum tubes mechanically expanded into full collar, aluminum or copper fins. Our three factories are highly automated, with automated fin press machines, hairpin benders, CNC machines, auto-brazing machinery, as well as the latest testing technology.

Coil Capabilities

We can handle almost any coil for both air conditioning and refrigeration: condenser coils, evaporator coils, and fluid coolers.

|

Coil Selection and Coil Rating

At CIG, we use a state-of-the-art HVAC coil selection program that automatically calculates the optimum size of the coil and number of rows, and fins per inch based on the stated performance requirements. Likewise, a given coil design can be rated for performance, calculating the amount of heat transfer to be achieved. The thoughtful and careful use of the selection program can yield the correct pressure drop at the lowest reasonable cost to fill a particular requirement.

Leak Testing

We operate four types of leak testing, including water tank testing, helium sniffer testing, fatigue testing and burst testing. Every coil and connecter that we make gets tested for leaks.

Bubble Leak Test. Every coil is subjected to an underwater bubble leak test at a minimum 380 psi. For higher pressure applications, we apply 600 psi up to 1,000 psi, according to our customer specifications. Tests are normally conducted for 10 minutes to identify leaks in brazing, which are then identified, marked and repaired.

Helium Vacuum Chamber Leak Test. Our #2 Factory in Chonburi is also equipped with a helium vacuum chamber to test for leaks per customer specification. A coil is placed in the enclosed vacuum chamber and then filled with helium gas. The leak detection is performed by a helium mass spectrometer that can detect even a few nanograms of escaped helium.

Helium Sniffer Leak Test. Our factories are also equipped with portable helium leak detectors. Specifically, we offer, according to customer specifications, full-time leak testing on the factory line by mass spectrometer leak sniffers that are made specifically for the HVAC industry.

Design and Performance Testing

In addition to the daily leak testing that we offer for each and every coil, we also perform tests on all new designs or specifications, including fatigue testing and burst testing. The industry trend toward smaller aluminum tubes and higher pressure calls for periodic testing to insure confidence in the final product.